The compact biogas plant

The compact biogas plant many rural household used biogas as cooking

food the tradition of domestic biogas plant require a daily input of

forty kilograms of dung mixed about forty litter of water it takes about

forty days for the dung to start producing biogas in order to

accommodate the daily input of forty kilo gram dung and retaining it in

to plant for forty days requires of plant having of very large capacity

up about four cubic meters because of the large size such a plant

requires a lot of space and it cost also high because of the moving

populations of cattle the availability of animal manure has declined

causing many of the existing biogas plants stop operation.

Related Posts

Construction of Portable Biogas Digester

VACVINA biogas Plant information and Construction Video

Building of Biogas Plant by Recycled Plastic Drum

Biogas Digester Photos

Arti biogas plant

Appropriate rural of technology institute (arti) has developed new

compact biogas system which is very easy to use. This biogas plant’s

works on starchy sugary cellulose or fatty substances. One can use non

vegetable oil seeds like pongamian, neem, caster, damaged or override

fruits, grains, flour mill wastes, fruits of vaecas non animal risen of

banana peel, or any other substance related feedstock, the feedstock

must be closed grand and applying to the biogas plant. After mixing it

with the about five to ten liters of water about one to one in half

kilo gram of starchy material would yield sufficient gas to cook the

meal is about four to five persons the amount of gas generated everyday

depends upon the capacity of the fermenter or bio gas digester and gas

holder fermenter capacity

Five hundred litters gas holder capacity four hundred available gas tow hundred and fifty liters duration of burning one hour

Digester capacity one thousand litters’ gas holder capacity seven

hundred fifty litters available gas 700 litter and duration of burning

two hours

Digester capacity two thousand five hundred letters

Gas holder capacity two thousand litters

Available gas one thousand seven hundred and fifty litters and duration of burning five hours

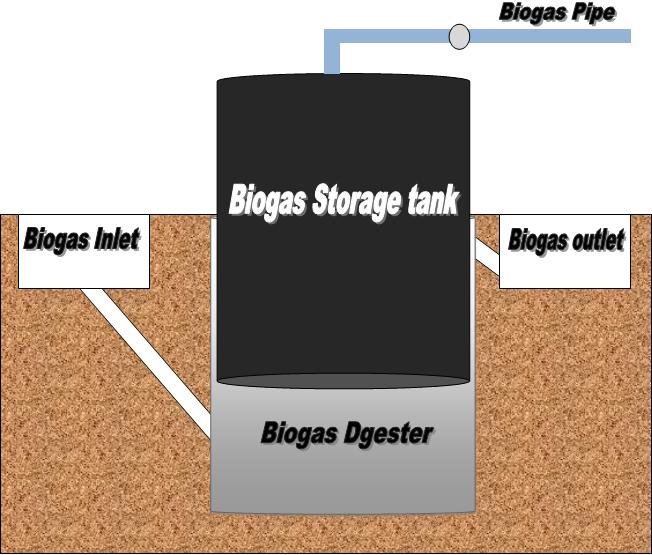

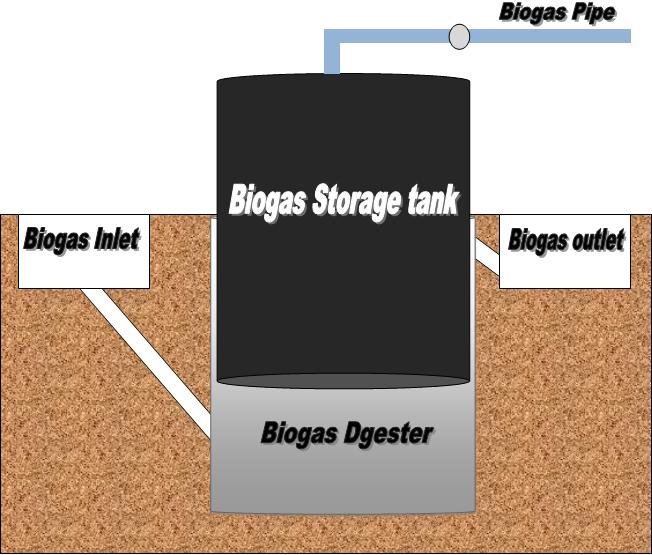

There are various ways which this biogas plants can be fabricated

this arti biogas plant has been fabricated that the help of tow plastic

tanks this one has a cement concrete tank has the fermenter or digester

and the plastic tank has a gas holder.

This third model tank has tank made by sheet metals. Although the

fermenter tank made of different materials the gas hold tank always made

of plastic.

How to make a Biogas plant digester by 1000 litter of water tank and gas holder tank 750 litter

Material required

- 1st 1000 litter Black colored molded plastic tank

- 2nd 7500 litter Black colored molded plastic tank

- 90 millimeter T one piece PVC

- 90 millimeter female adapter 1 piece PVC

- 90 millimeter male adapter 2 piece PVC

- 90 millimeter cap 1 piece PVC

- 2 meter 90 millimeter diameter 1 piece PVC Pipe

- Elbow 63 millimeter 1 piece

- 60 millimeter male adapter 2 piece PVC

- 60 millimeter check nut 1 piece PVC

- 63 millimeter PVC pipe 90 centimeter long

- 12.5 PVC mail adapter 1 piece

- 12.5 Millimeter iron elbow

- Epoxy risen and hardener

- PVC cement Solution

- Biogas Stove

- PVC valve 50 millimeter dia

- And tools

- 90 millimeter barrel piece

- 63 millimeter barrel piece

- 50 millimeter barrel piece

- 12.5 millimeter barrel piece

Construction of ARTI Compact Biogas Plant

First Take the one thousand liter tank cut in this manure

perforated near the base By pressing Preheated Nineteen mm barrel piece

against than perforated tank Also near the bottom but With fifty

millimeter bout of peace Prudhomme of this position Would be helpful b

sixty three millimeter barrel peace

Make a third holes one this position with the help of 63 mm barrel piece

The tank as three holes 2 near the bottom and 1near the top

Now PVC glue to the nineteen millimeter main adopted And fix it into

this ball from inside the trades no protrude out of the tank fixed.

Page is still updating.

See Also

Making of DIY Biogas Plant, Anaerobic Digester Experiment Concept The

purpose of this project is to discover ways to produce Biogas with

alternate sources by using our local resources this project can help

students to basics of Anaerobic digestion and…read more

DIY Biogas Plant

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)